How to use the 3D Printer Filtration System V1?

3D Printer Filtration System V1 Unboxing Video

Installation Guideline

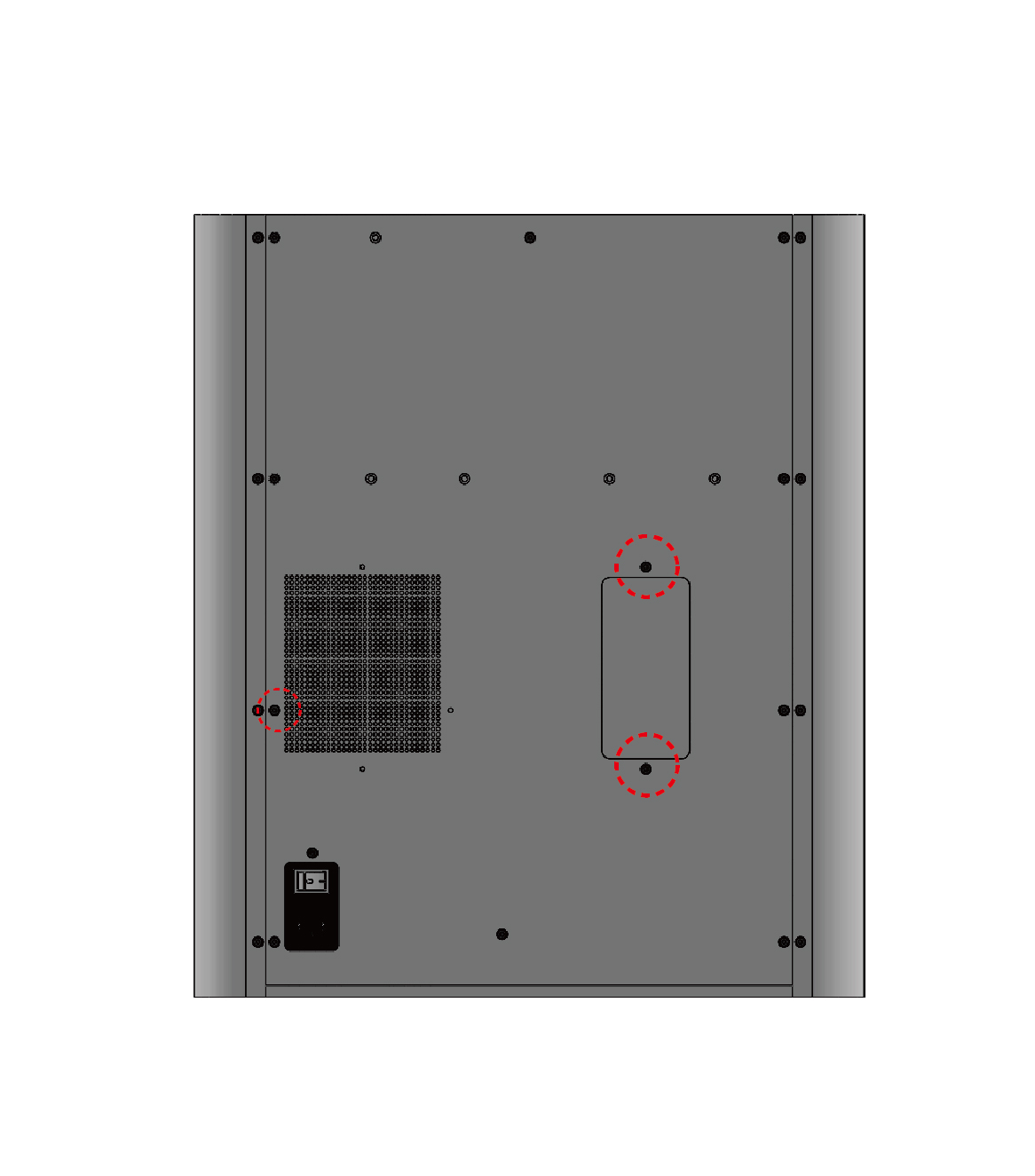

1. Remove Screws from Back of Printer

Refer to the illustrations in the manual.

*Keep the two screws on the right side for use in the next step.

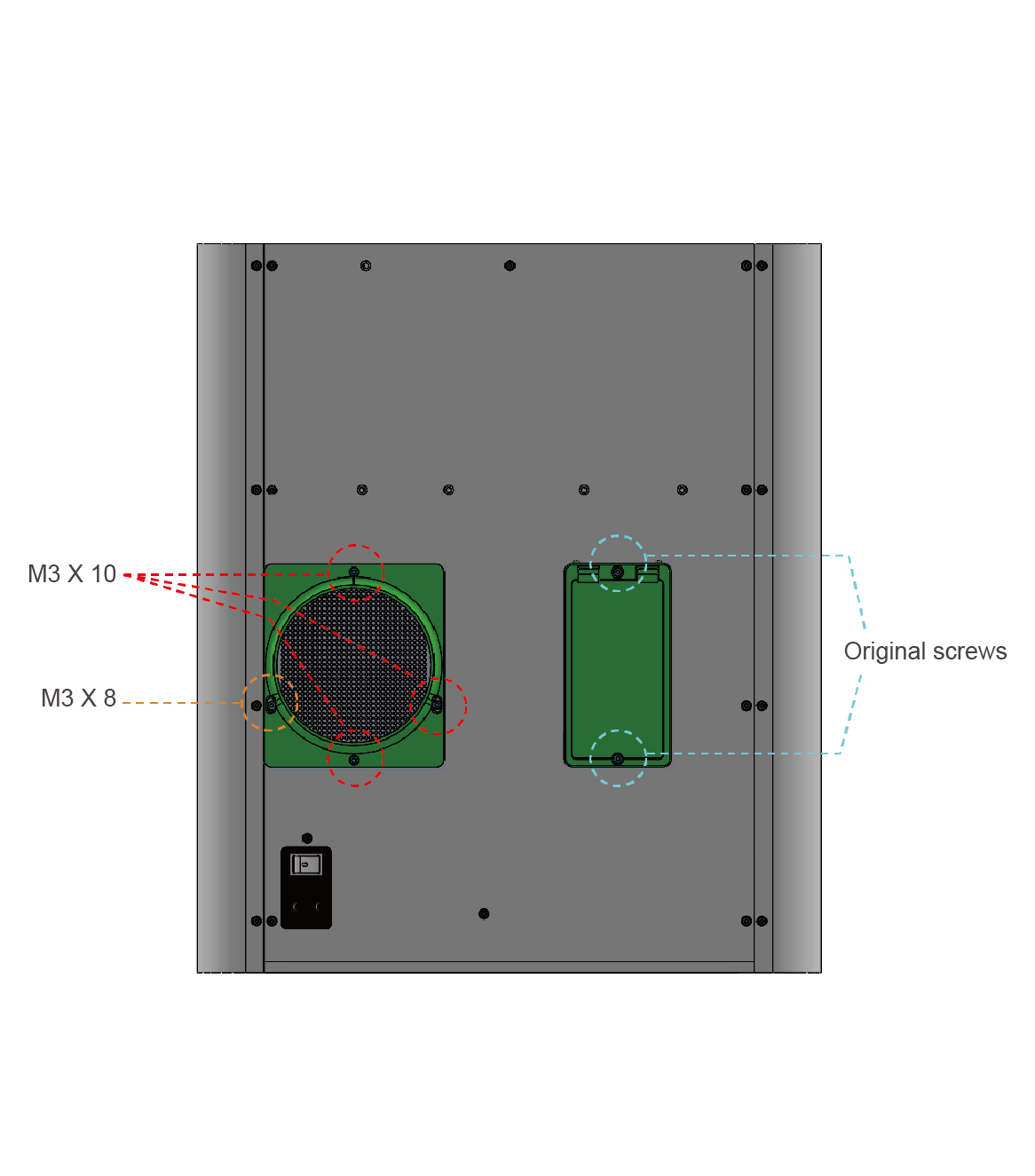

2. Install Filter Interface &Waste Outlet Cover

Attach them securely to the machine.

CONNECT POWER SUPPLY

Connect the provided 24V DC adapter to the power input socket.

HOW TO OPERATE THE FILTER

Turn the speed control dial clockwise to power on and increase filtration efficiency.

Turn it counterclockwise to reduce filtration efficiency.

WHEN TO USE THE FILTER?

1. For High-Temperature Materials (e.g., ABS, ASA, Nylon, PC)

At the start of printing, it is recommended to set the power dial to no higher than 20%. This helps maintain the chamber temperature. After printing is completed, turn the dial to 100% and let the filter run for 10 minutes before opening the chamber door to remove the printed part.

Since different filament brands have varying characteristics, enabling the filter while printing ABS, ASA, or PC may lead to print quality issues, such as visible layer lines. In such cases, the power level should be reduced. For larger and taller models, especially those covering more than 50% of the build platform, it is recommended not to use the filter during printing.

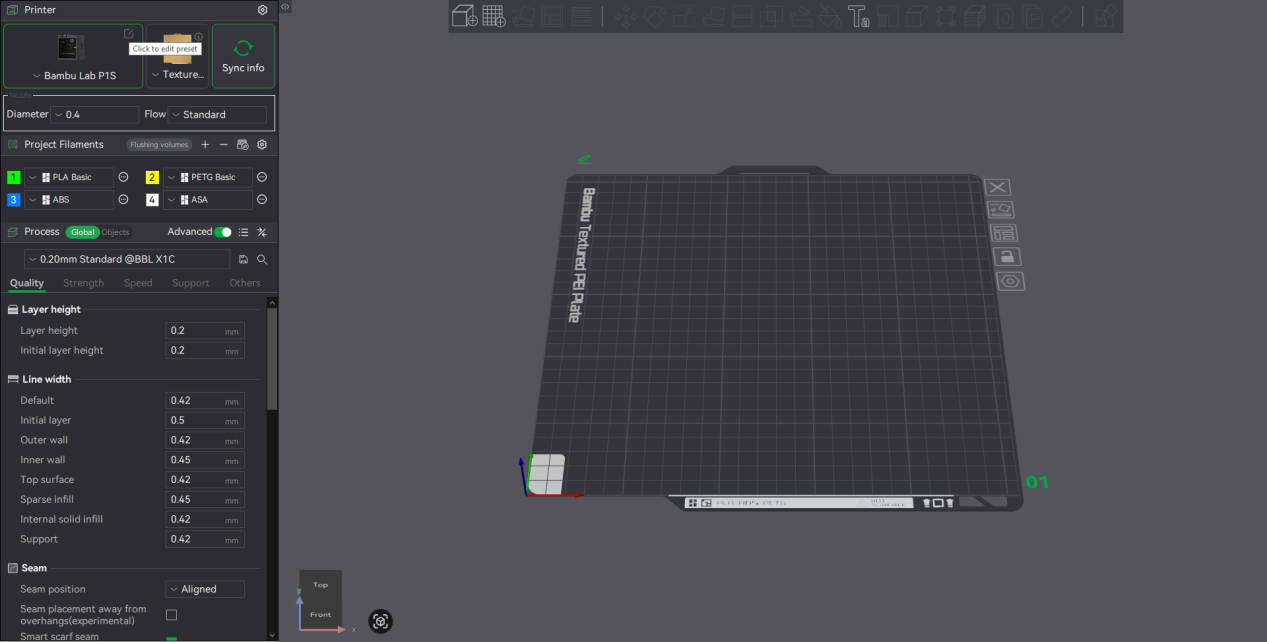

2. For Common Materias(e.g.,PLA, PETG, TPU)

It is recommended to keep the filter on during printing. However, you must also enable the Aux Fan and Exhaust Fan in the slicing software settings. The dial should be set to below 50% during printing.

After printing is completed, turn the dial to 100% and let the filter run for 10 minutes before opening the chamber door to remove the part.

3. How to Shorten Post-Print Filtration Time

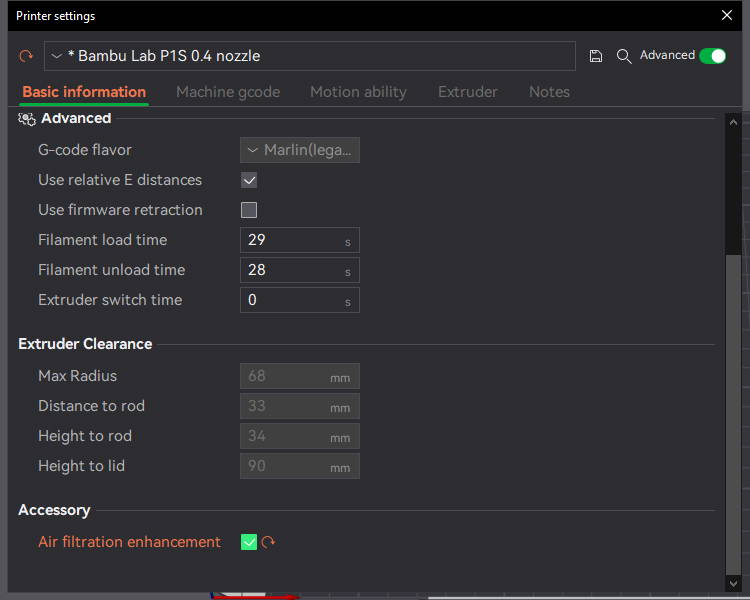

You can adjust printer settings in the slicing software:

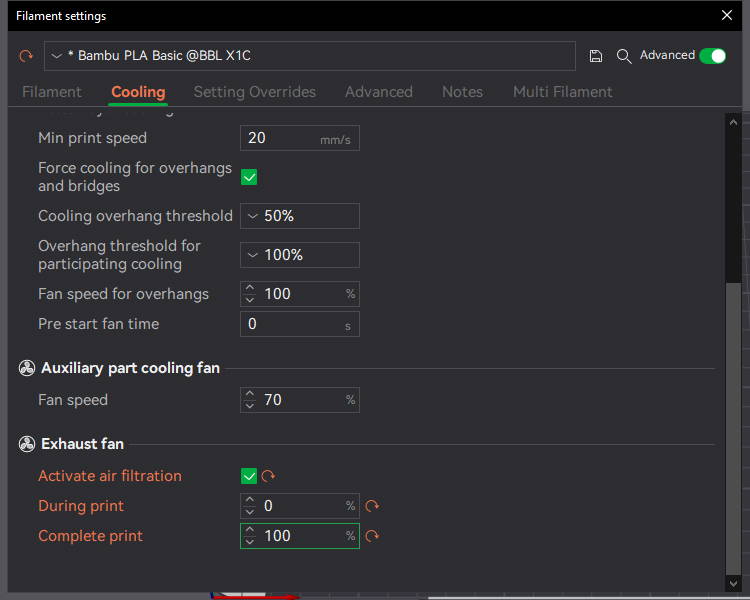

Enable Air Filtration Enhancement.

In the material settings,configure the printer to automatically run the Exhaust Fan at 100% after the print is finished.

(Settings for other materials can be adjusted according to the above principles.)

LIFETIME OF FILTER CORES

We suggest changing the filter cores together. Usually, the filter cores are used for THREE MONTHS, estimated by 8 hours printing per day, but it depends on your printing hours and filament material. A relatively simple way to judge is that when you smell an odor, it means that the filter cores need to be replaced.